Improving Medical Device Reprocessing Department

Human-Centered/ Service Design Project

Improving Medical Device Reprocessing Department (MDRD) system at University Health Network (UHN), Toronto using user-centered Service Design method.

Background

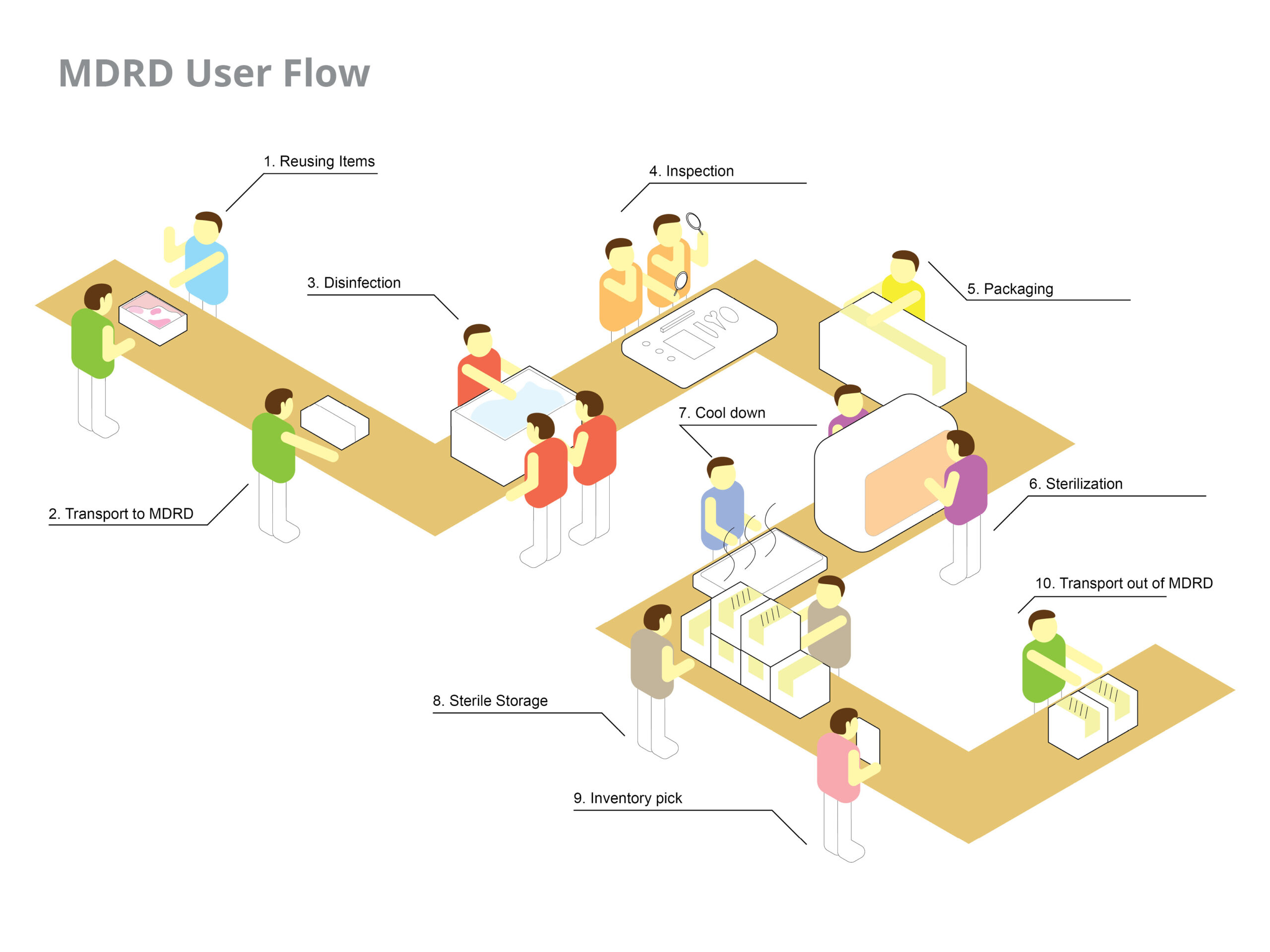

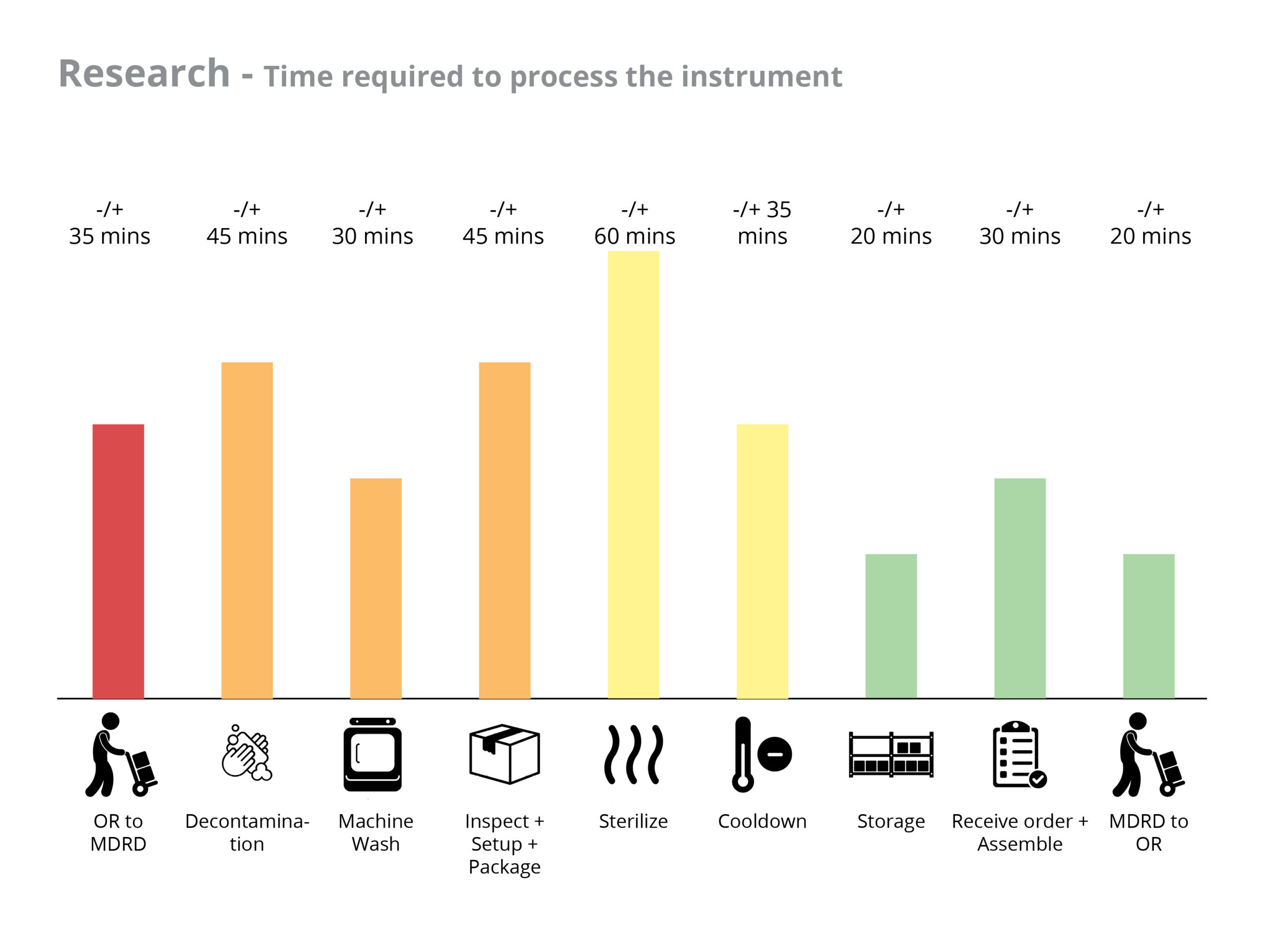

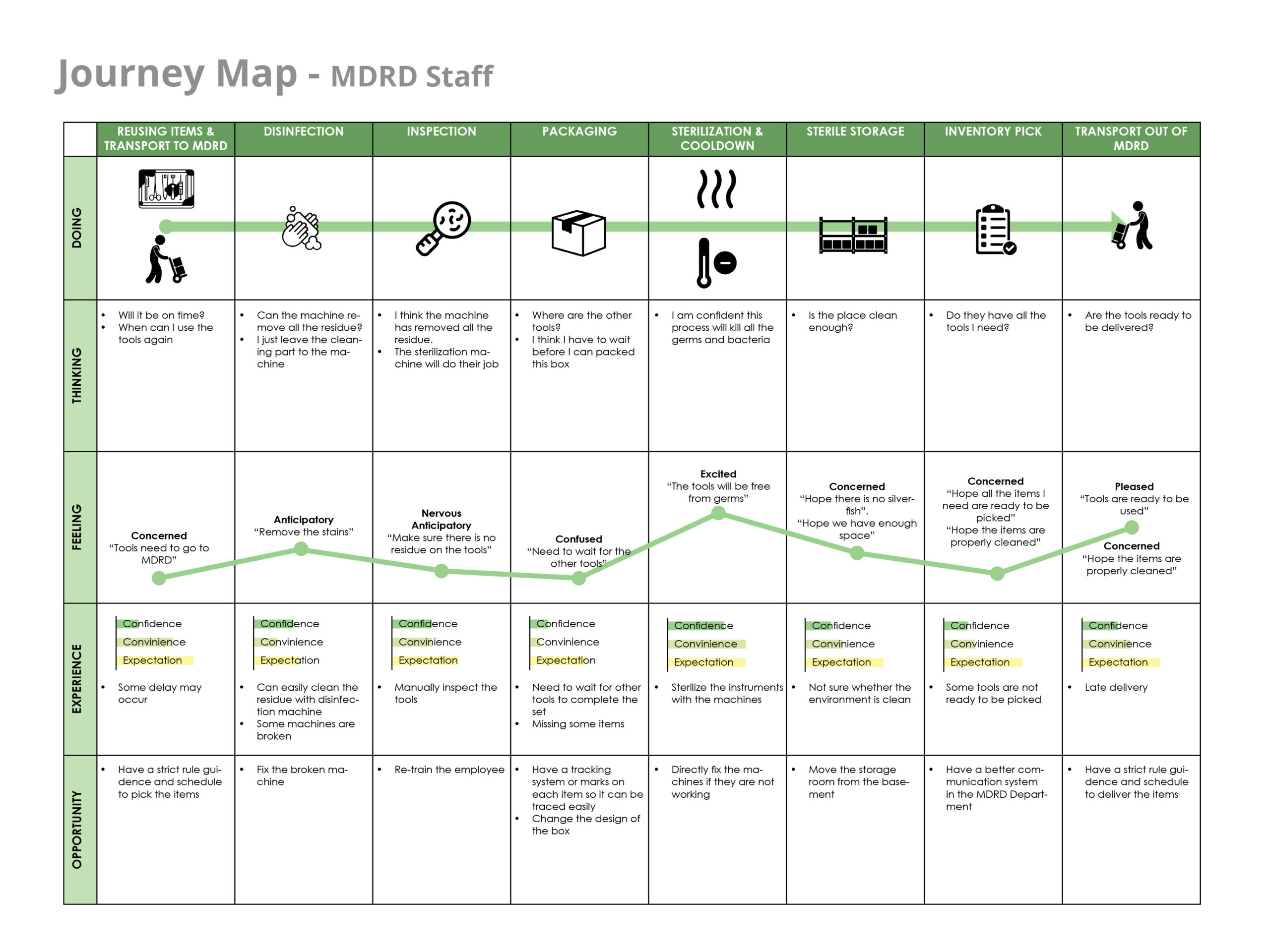

Surgery does not start in the operating room (OR), it starts in the place called Medical Device Reprocessing Department (MDRD), where surgical instruments are cleaned and reassembled.

Analysis of the current state of operations in MDRD presents many challenges: trays missing sterile indicators, compromised instrument inspection, broken instruments in sets, missing instruments from trays, and rescheduling patient surgeries due to unmet demand which can cause bigger problems such as unsterile surgical tools and cross-contamination.

UHN’s Medical Device Reprocessing Department (MDRD) reprocesses over 400 trays of instruments a day. In 2019, the failure rate to deliver a clean-complete instrument by MDRD reached 30%

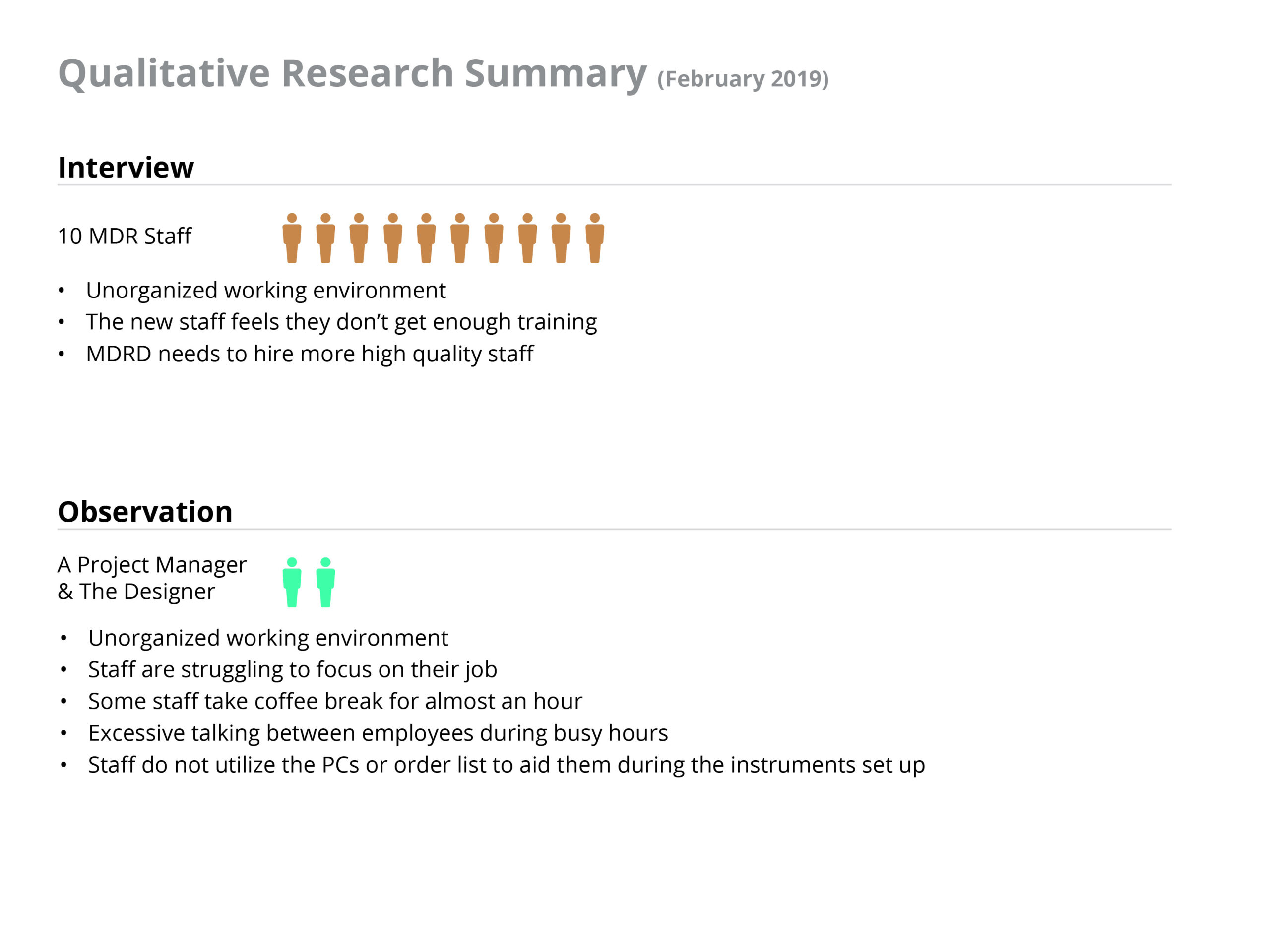

Primary Research – Ethnographic and Primary Research (one-one-one interview)

Some of the factors based on the primary research are:

- Unorganized working environment and workstations

- Stressful and busy routine

- Assembling surgical instruments is a demanding task

- Patient safety adds to the burden of preparing surgical instruments

- Sometimes, missing and broken instruments are not foreseen by MDR staff.

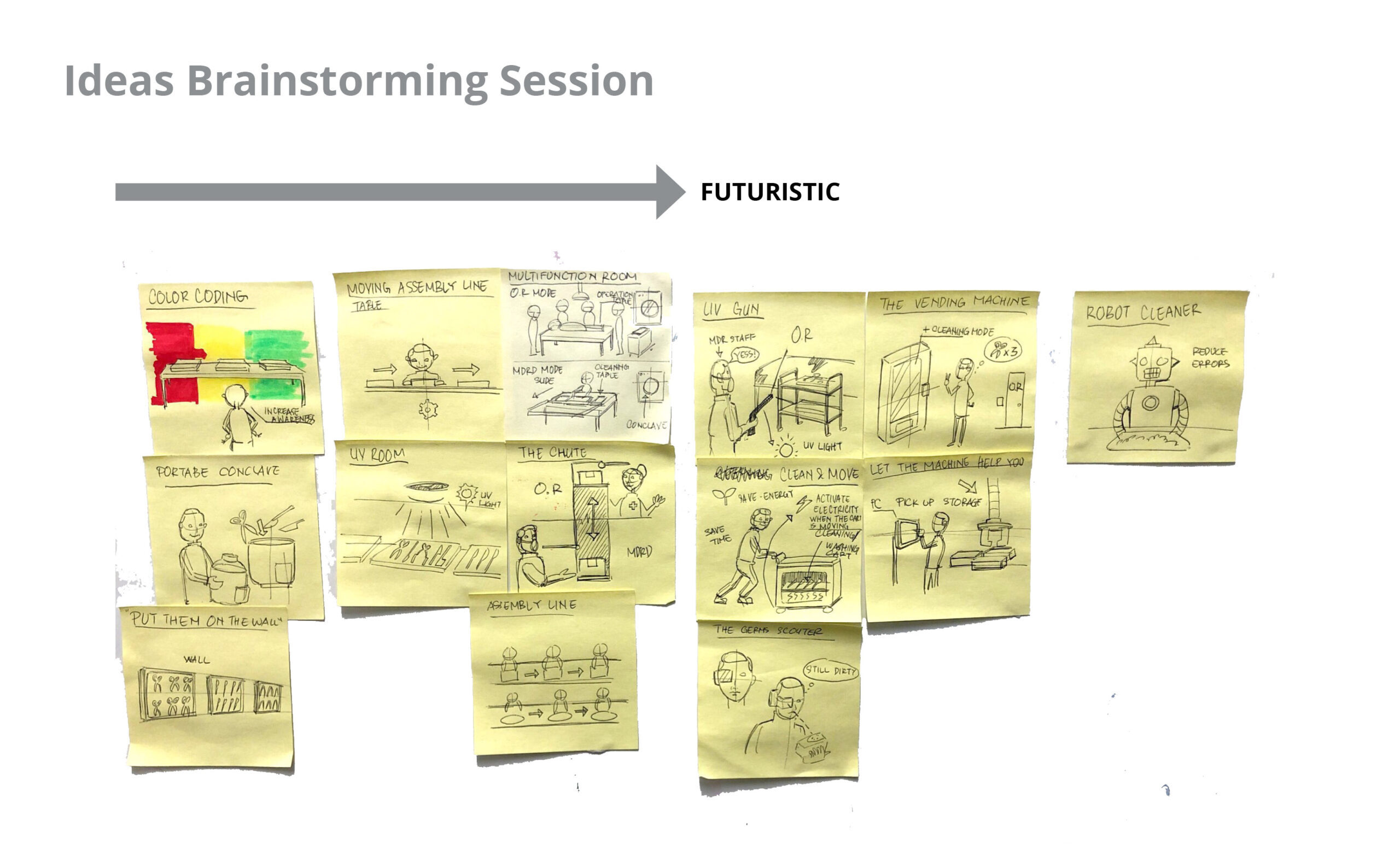

Based on the co-design session, new strategies need to be implemented to address the service and system issues, thus preventing the MDR staff from making errors.

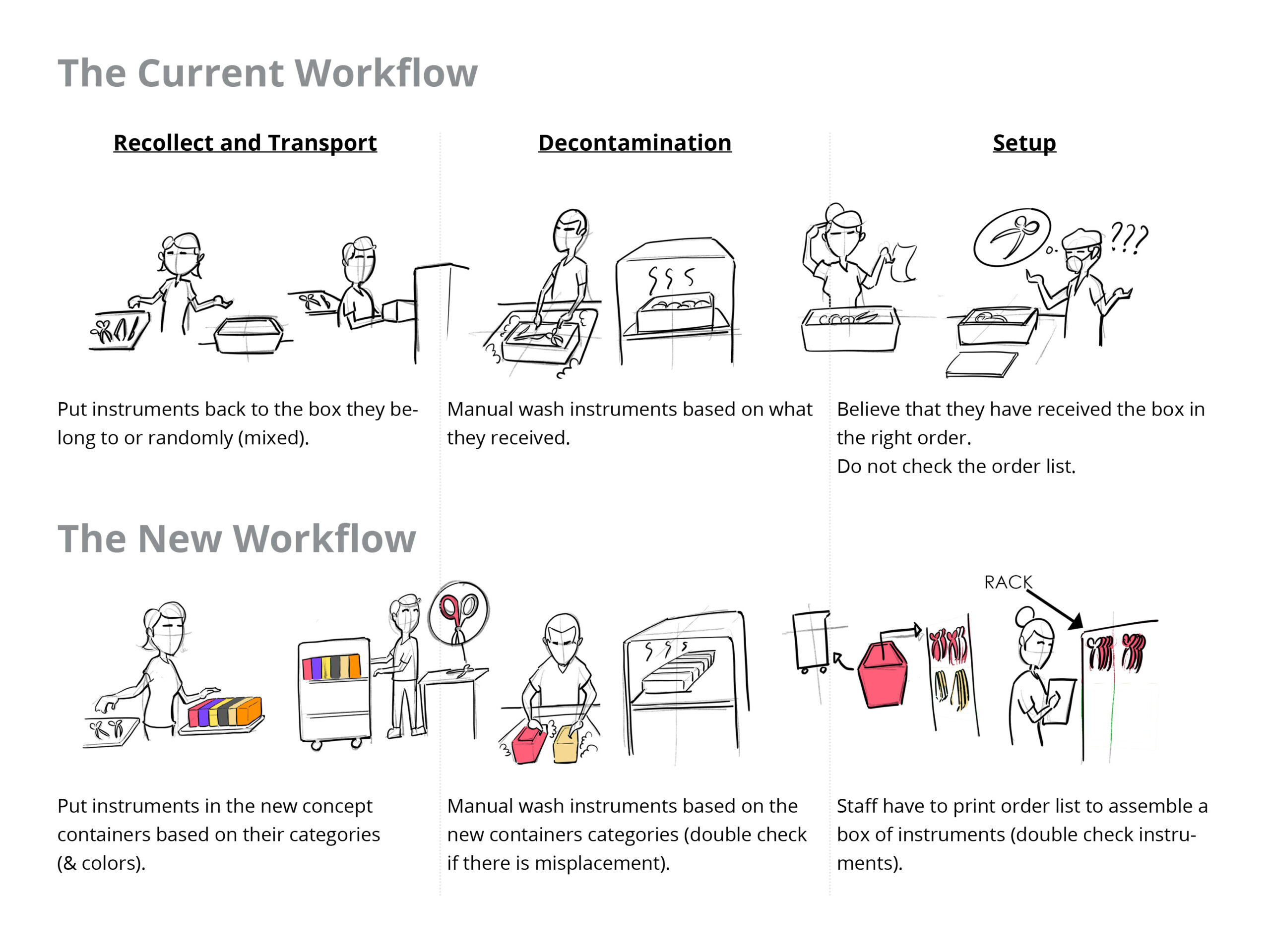

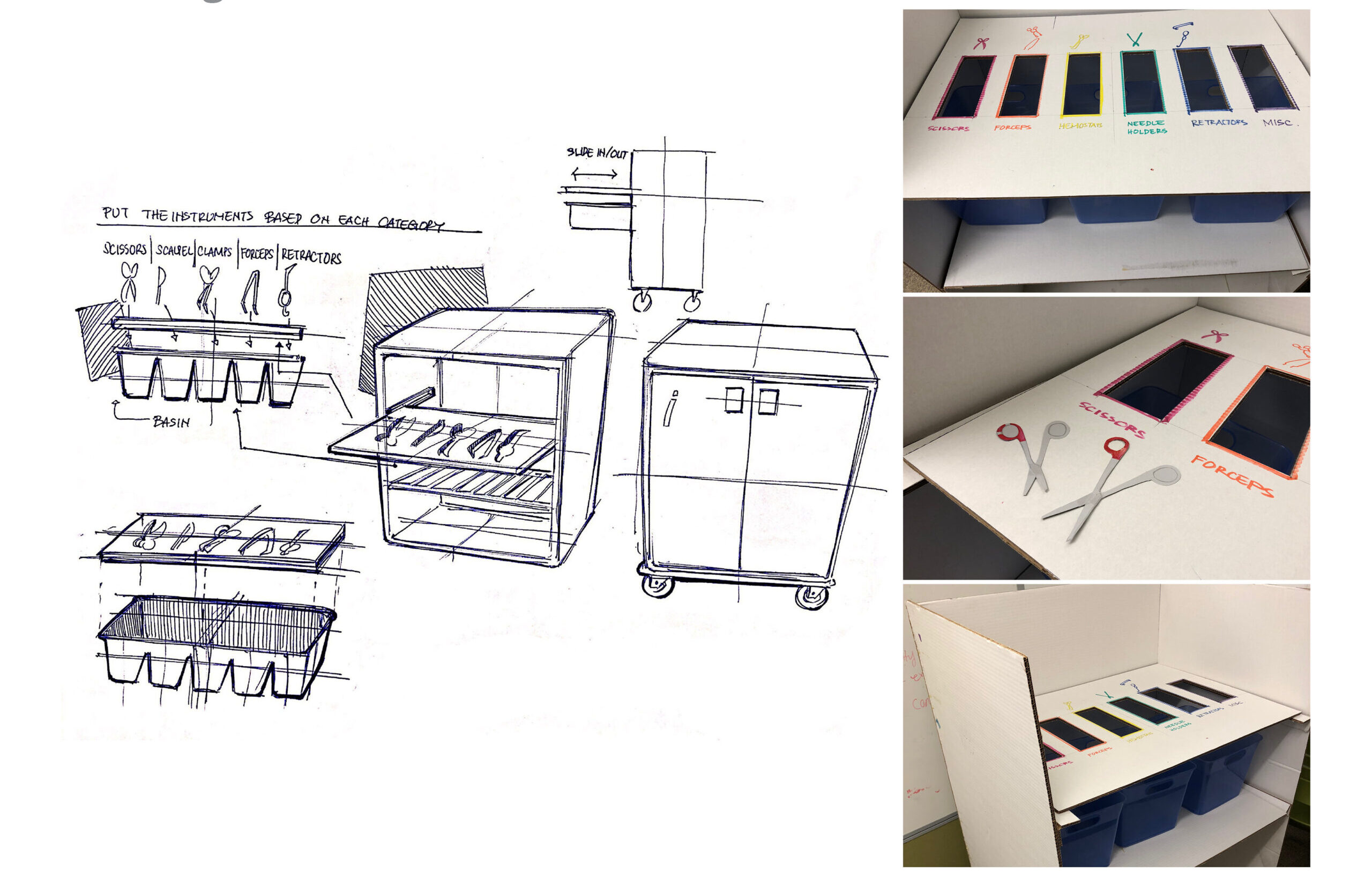

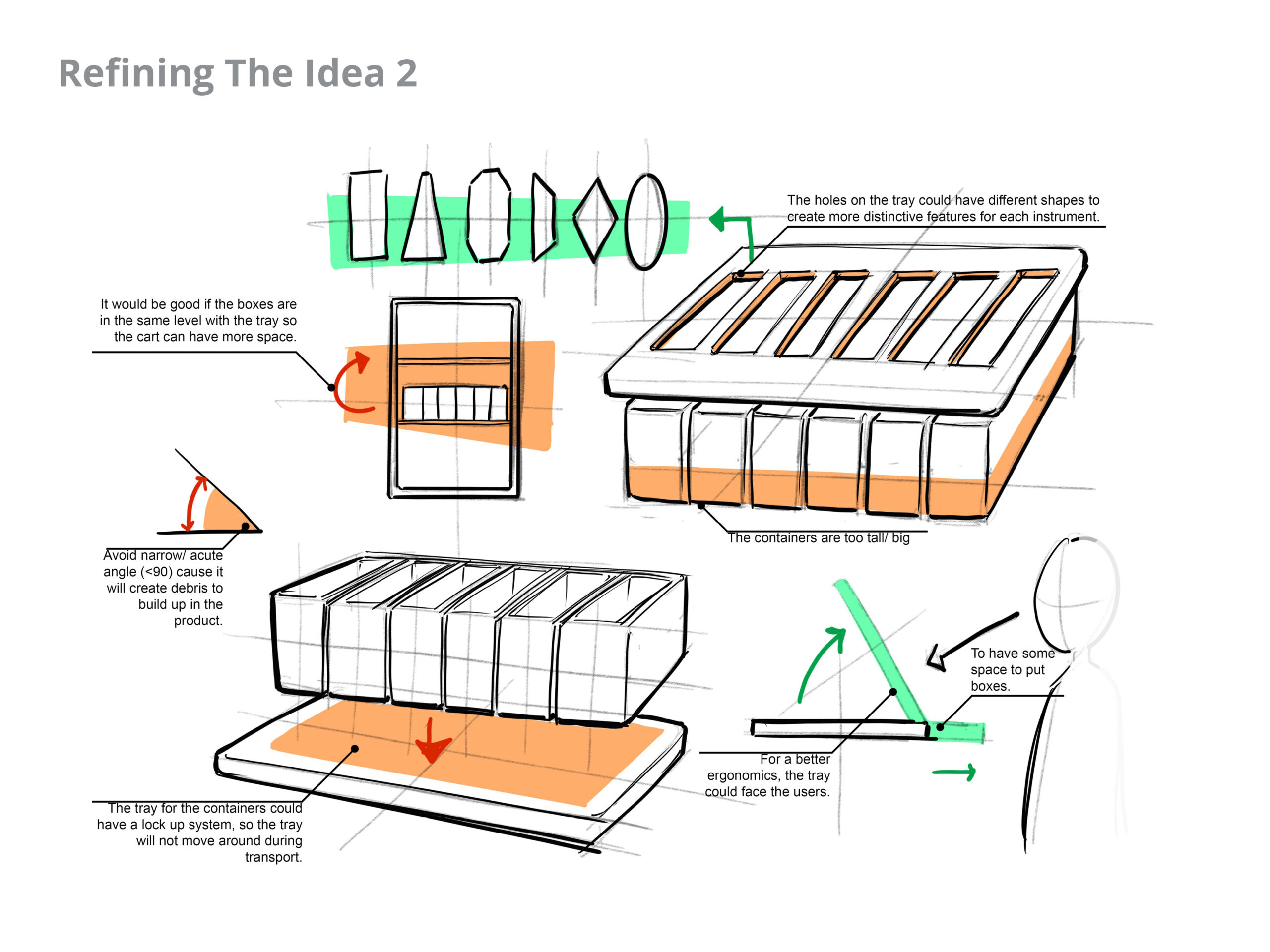

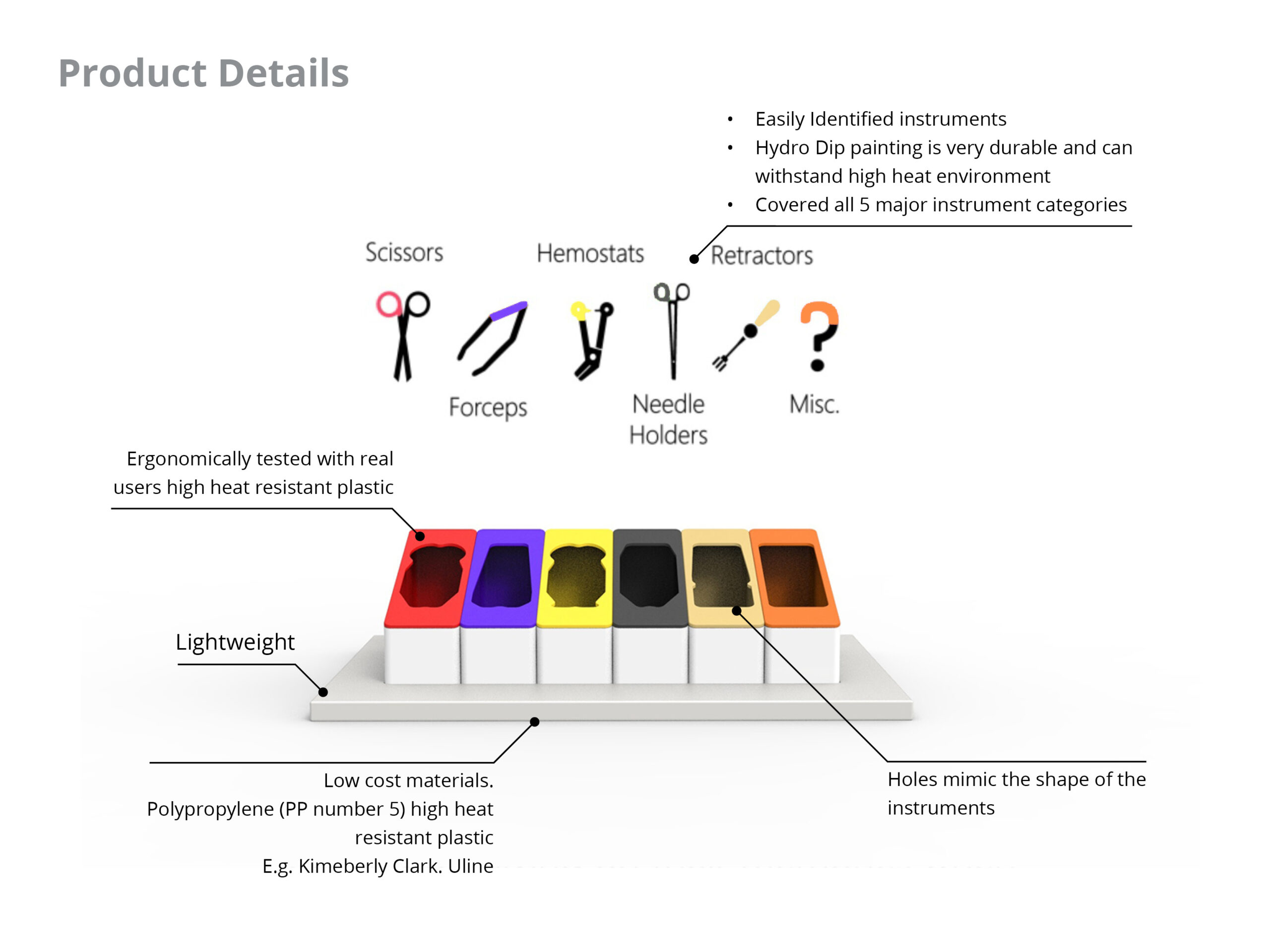

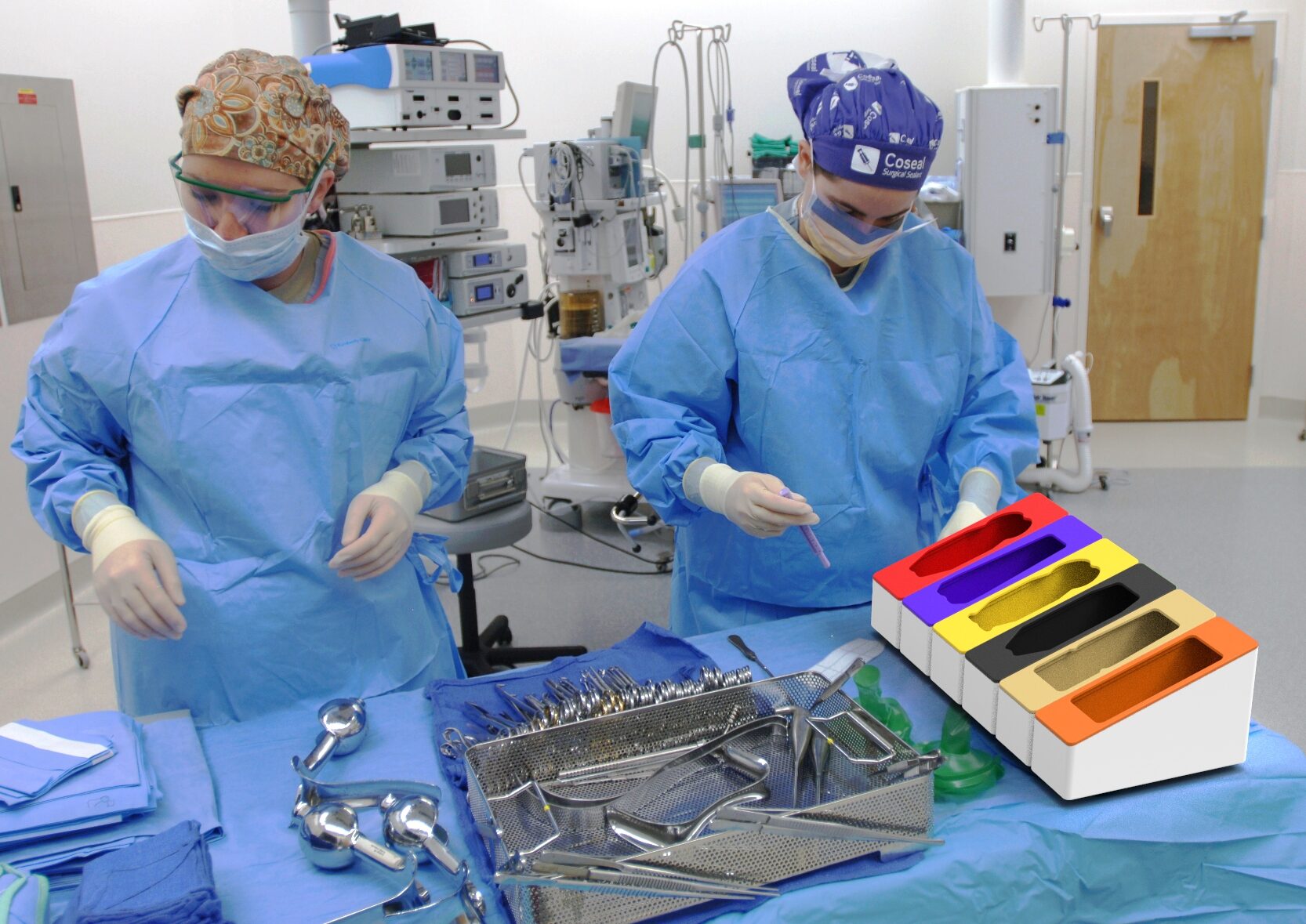

The idea of a color-coding concept in the MDRD facilities was developed to make instrument identification effortless, keep the instruments organized, and reduce/ eliminate the possibility of instrument misplacement.

The color-coding concept is intended to enhance the current MDRD system. With the new system, staff will automatically be encouraged to double-check the instrument placement in each phase of the reprocessing process.